| 表面處理器材 |

|||||||||||||||||||||||||||||||||

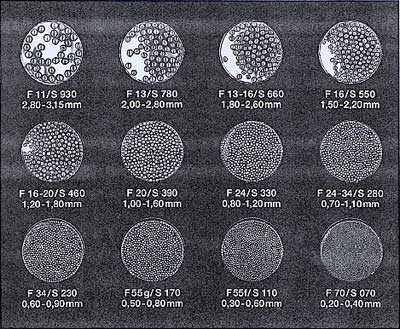

| Low Carbon Steel Shot FERROSAD FERROSAD low carbon steel shot gives a longer life and is more durable than high carbon shot because it is relatively crack free. With high carbon material the shotting operation produces surface cracks which are extended in subsequent heat treatment. This does not occur in low carbon shot because of its different structure. Microstructures - the low carbon shot is produced by melting only deep-drawing low carbon scrap. As a result of this the microstructure after the atomizing process is a bainite structure (isothermal transformation), which is tough and durable. The high carbon shot is produces by using all kinds of scrap. Therefore the shot particles after atomizing into water are very hard with surface cracks. The shot has to be heat treated by quenching and tempering to remove the very coarse martensitic structure. During this process the surface cracks can be extended. |

|||||||||||||||||||||||||||||||||

| Chemical Analysis - all figures are approx. values | |||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| Durability As low carbon shot has a bainite structure and does not have cracks the consumption has been reduced by more than 20 % in trials by our customers factories compared with high carbon shot. |

|||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

|

Copyright

(c) 2005 CHAO SHUN ABRASIVES CO., LTD.~ All rights reserved. |